-40%

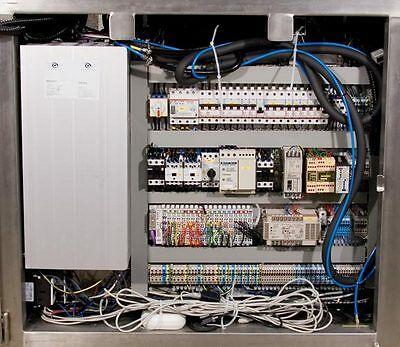

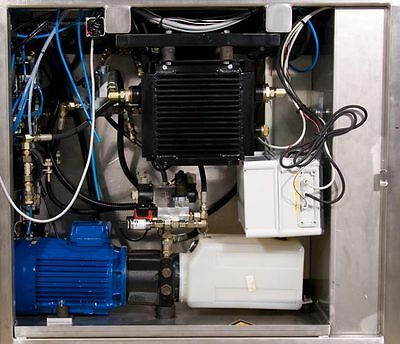

Obducat NIL-4 Nano-Imprinter/Imprint Lithography System

$ 21119.99

- Description

- Size Guide

Description

Obducat NIL-4 Nano-Imprinter / Imprint Lithography SystemComes with a manual and what you see in the pictures. If you don't see it, you probably wont get it.

Specifications are from Obducat and may vary slightly due to upgrades, options, or revisions this unit may or may not have.

We do not have the expertise to test this unit.

The Unit's Serial Number Tag Reads:

Type:

Imprinter

Model Number:

NIL-4

Serial Number:

4.02-001

Power Requirements:

208 VAC, 3-Phase, 60 Hz

Manufacture Date:

2002

CE Marked:

Yes

The Cooling Bath's Serial Number Tag Reads:

Type:

CBN 18-30

Serial Number:

802080077

Power Requirements:

230 V ~, 3.4 Amps, 50 Hz, 690 W

Refrigerant Type:

R 134a

Refrigerant Amount:

260 g

IP-Class:

IP21D

CE Marked:

Yes

The Thermostat's (Part of the Bath) Serial Number Tag Reads:

Type:

HMT200

Serial Number:

802090177

Power Requirements:

230 V, 50 Hz, 1600 W

IP-Class:

IP20

CE Marked:

Yes

Specifications:

Stamper:

Material:

Nickel

Thickness:

0.25 - 0.32 mm (Max. 0.65 mm)

Outer Diameter:

130 mm +4 mm / -1 mm

Flange Position:

134 mm

Imprinting Area:

≤ 102 mm Ø

Substrate:

Material unknown

Flexible and rigid

Substrate Size:

≤ 200 mm (diameter for round or diagonal for square)

Substrate Holder(s):

6 inch diameter for round and flat (flexible and rigid samples)

6 inch diagonal for square (flexible and rigid samples)

Two different holders must be provided

Manual Material Load:

User-friendly method for loading work material onto NIL-4

Sample loader capable of handling flexible and rigid core material in specified sizes

Imprinting:

Two-sided imprinting

Alignment:

The two stampers are aligned with an accuracy of 10% of fiducially size with 1 um limitation

Alignment module is integrated into the press-head

Alignment module is optical

Semiautomatic alignment is carried out by means of X, Y, Theta motors

Heating of substrate

To a max. of 350°C with a temperature setting accuracy ±2.0°C

Temperature differences across active surface is within ±0.5% of the temperature

Heat-up ramp > 5°C/second

Substrate Cooling Capability:

Is available

Pressure:

Max. 60 bar.

Demold:

NIL-4 has two-sided auto demolding function resulting in no imprint deformation on substrate.

Manual Material Unload:

Sample unloader is operated manually and safely when material is at high temperatures.

Configuration Options:

Programmable recipe software:

Sequence is: first heat, then press

Pressure and position vs. time

Closed feedback loop to ensure accuracy

Equipment Footprint:

≤ to 1000 mm x 750 mm

Environment Limitations:

External temperature: 18 - 22°C ±1°C

Will require additional cooling for keeping ambient constant

Max. relative humidity: 65%

Clean Room Performance:

Class 10 for press module

Class 1000 for rest of NIL equipment

Mains Requirements:

208 VAC ±10%, 3-Phase, 60 Hz

Markings and Regulations:

CE-mark

CE approved Mains disconnect switch with lockout / tagout capability

Interlocked safety covers restricting access to any hazardous energy, including movement

EMOS

0.00 minimum for packaging, handling, and order processing. Shipping to be determined by destination.

Prior to shipment I will need to know the following information (filled out on a form that I will send you) for International Customers or Packages/Freight being Forwarded internationally. International customers may also be subject to a freight forwarder form if applicable.:

(1) Are you the end-user of this item?

(2) If you are not the ultimate end-user of the item, please state the ultimate end user's name.

(3) What is the ultimate country destination?

03/05/08